When a homeowner decides to replace his current water heater, there are several options to consider. The two main options for water warmers are tank and tankless water heaters. Most houses have tank water heaters, which take water into an insulated tank and heat it until the water is sent to various locations within the house. However, these traditional water heaters take up a lot of physical space and routinely run out of heated water, especially with large households. In comparison, tankless water heaters more efficiently use energy, space and money.

A tankless water heater heats the water as it flows through a heat exchanger coil. And unlike traditional hot water heaters, tankless water heaters do not retain any water except for what is in the heat exchanger coil. The other charm of a tankless water heater is that it produces hot water on demand. No longer does the user have to wait for a storage tank to fill in order to receive endless hot water.

Most tankless water heaters provide hot water at a rate of two to five gallons per minute; gas fired tankless water heaters produce higher flow rates than electric tankless water heaters. Because they take up little space, some households opt to install two or more tankless water heaters. This allows a house to have specific water heaters for hot water hogs such as washing machines, dishwashers and pools. When deciding which water heater to purchase, consider where you need hot water. Decide whether you need the water throughout the entire house, in one room or at one appliance. Determine the number and type of fixture that will need a hot water heater because each fixture requires different amounts of hot water.

Before purchasing a tankless water heater – Stiebel Eltron,

Rheem and Takagi are major manufacturers - decide whether you would like an electric or gas fired tankless water heater. With an electric tankless water heater, an electric element heats the water as it enters the unit through a pipe. If you plan to purchase an electric tankless water heater, you will have to understand how much voltage and amperage your house can accommodate. You should take into account how the hot water heater will affect the circuits in your house because it may be necessary to put your electric tankless water heater on its own circuit. Before installing an electric water heater, consult a licensed electrician for more information.

With gas-fired tankless water heaters, a gas burner heats water as it enters the unit. If you plan to purchase a gas-fired tankless water heater, you will have to understand the different types of fuel that fills the tankless water heaters. Users should examine their current gas line to ensure that it can accommodate the requirements of your new gas-fired tankless water heater. Next, you will need to consider venting requirements for your water heater. Also, be sure to check local building code to ensure compliance of regulations.

This is a natural shift from old technology to new. Traditional hot water heaters will remain in use for a short while as more homes transition into the more efficient, space-saving tankless models.

When a homeowner decides to replace his current water heater, there are several options to consider. The two main options for water warmers are tank and tankless water heaters. Most houses have tank water heaters, which take water into an insulated tank and heat it until the water is sent to various locations within the house. However, these traditional water heaters take up a lot of physical space and routinely run out of heated water, especially with large households. In comparison, tankless water heaters more efficiently use energy, space and money.

When a homeowner decides to replace his current water heater, there are several options to consider. The two main options for water warmers are tank and tankless water heaters. Most houses have tank water heaters, which take water into an insulated tank and heat it until the water is sent to various locations within the house. However, these traditional water heaters take up a lot of physical space and routinely run out of heated water, especially with large households. In comparison, tankless water heaters more efficiently use energy, space and money.

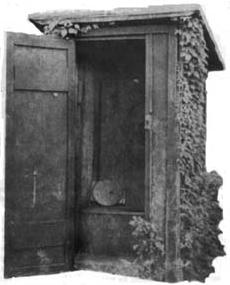

Left: An early 20th century outhouse with a fanciful design.

Left: An early 20th century outhouse with a fanciful design.

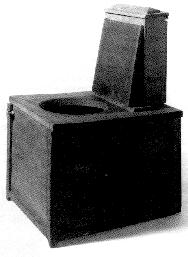

Left: An earth closet used indoors used fresh earth or ashes on the bottom of the wood structure to absorb ordors.

Left: An earth closet used indoors used fresh earth or ashes on the bottom of the wood structure to absorb ordors.  Left: This wooden box encloses a square water closet from early American days.

Left: This wooden box encloses a square water closet from early American days.  One source of a leaky toilet is loose nuts where the tank is attached to the bowl. To tighten the nuts in the tank use a flathead screwdriver to steady the bolt inside the bowl while using an adjustable wrench to tighten the nut on the underside of the tank.

One source of a leaky toilet is loose nuts where the tank is attached to the bowl. To tighten the nuts in the tank use a flathead screwdriver to steady the bolt inside the bowl while using an adjustable wrench to tighten the nut on the underside of the tank. Reposition the Float Ball

Reposition the Float Ball Adjust the Water-Intake Assembly

Adjust the Water-Intake Assembly Flapper or flush valve needs servicing

Flapper or flush valve needs servicing